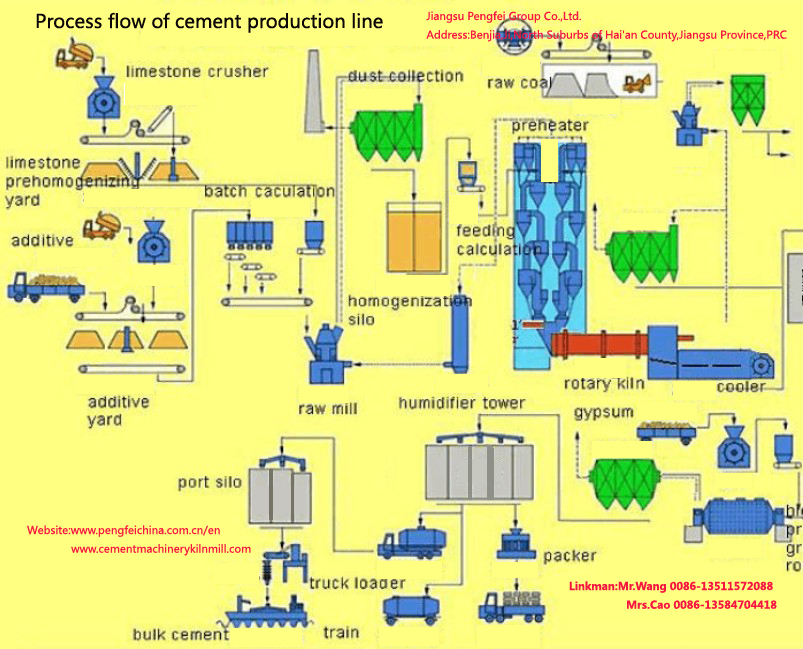

Description of New Type Dry Process Cement Production Line:

This new type dry process cement production line is a kind of process mainly used for small, medium and large-scale cement plants. Its preheater employs outside kiln precalciner. Capable of utilizing the waste heat from kiln inlet to decompose raw meal, this line is good at saving electricity and heat. Its closed production line makes it possible to reduce its ambient dust pollution to less than 50mg/Nm3. Besides, its capacity to make use waste heat makes it quite cost efficient for users.

Production Flow of New Type Dry Process Cement Production Line:

1. Crushing and Pre-homogenizing:

Most of the raw materials, like limestone, clay, iron ores, and coal, should be crushed before their pre-homogenization. Limestone is the primary material in this line, and due to its large particle size and high hardness, its good crushing plays an important role in the whole line. Special stacking and reclaiming technology has been used in the pre-homogenizing process so that raw materials can be better primarily homogenized.

2. Raw Meal Preparing:

Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, it is quite important to choose appropriate grinding equipment and technological process so that high-quality products can be obtained.

3. Raw Meal Homogenizing:

The raw meal homogenization is a key factor for stable clinker calcination.

4. Preheating and Decomposing:

The preheater is used to preheat as well as decompose raw meal. So the length of the rotary kiln is effectively shortened. And the raw meal can fully exchange heat with the hot gases from the kiln. Because of its rapid and high-efficiency heat transfer, the production efficiency and heat consumption of this production line are greatly improved.

5. Clinker Calcining:

After its preheating and pre-decomposing, the raw meal will be calcined in the rotary kiln, where the generated carbonate will be further decomposed. Meanwhile, a series of solid phase reactions will take place.

6. Cement Grinding:

As the last process, the cement grinding will consume a great deal of electricity. And in this process, special size granule cement will be obtained.

7. Cement Packaging:

The cement can be transported in bulk or in bags.Quotation sheet of the 600T/D cement project

| NO | Name of the project | Price(RMB) | Price(USD) |

| ONE | Main production department 主要生产系统 | ||

| 1 | Limestone crushing 石灰石破碎 | ||

| 2 | pre-homogenizing stacking yard and clay and sandstone yard 预均化堆场、粘土& 砂石堆场 | ||

| 3 | Raw material storage 原料筒仓 | ||

| 4 | Raw meal grinding mill 生料磨 | ||

| 5 | Raw meal homogenizing 生料均化 | ||

| 6 | Kiln rear 窑尾 | ||

| 7 | Kiln medium 窑中 | ||

| 8 | Kiln head and clinker transportation 窑头&熟料输送 | ||

| 9 | Coal preparation 煤粉制备 | ||

| 10 | Clinker storehouse 熟料筒仓 | ||

| 11 | Cement grinding mill 水泥磨 | ||

| 12 | Cement storehouse 水泥筒仓 | ||

| 13 | Packing and finished-product storehouse 包装&成品筒仓 | ||

| 14 | Mixture drying 混合料烘干 | ||

| mechanical equipment subtotal 机械设备 | |||

| 15 | Air compressor room 空压机房 | ||

| 16 | Laboratory equipment(chemistry、physics) 实验室设备(化学、物理) | ||

| 17 | Workshop electrical, instrumentation and control 车间电气、仪表、控制 | ||

| 18 | Wire,cable 电线、电缆 | ||

| 19 | water supply and drainage 供水、排水系统 | ||

| 20 | Grinding body研磨体 ~210t | ||

| 21 | non-standard pieces 非标件 | ||

| 22 | heat insulating material 保温材料 | ||

| 23 | refractory material 耐火材料 | ||

| 24 | Casting Material 浇注料 | ||

| 25 | Commissioning oil 试运行用油 | ||

| nonprocess equipment subtotal 非工艺设备 | |||

| 25 | commodity inspection fee 商检费 | ||

| 26 | export packing fee 出口包装费 | ||

| 27 | Freight(NANTONG PORT) 运费(南通港) | ||

| Total 合计 |

Ps: The technical equipment sheet and quotation above differ depending on different raw materials and working conditions of various cement plants. This plan is just for reference only.The quotation is based on standard capacity 600tpd.

=====================================================================================================================

As world-known and high-quality cement machinery general contractor, Jiangsu Pengfei Group Co., Ltd can provide you with various machines, such as cement production line, cement grinding plant, active lime production line, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, drying equipment, cooling equipment, compound fertilizer equipment, Conveying Lifting Packing Equipment, Most of our products have passed the certification of ISO9000 and CE, and they have been quite popular among customers from as many as 60 countries and districts such as Germany, Russia, Brazil, Egypt, Japan, South Korea, Bengal, Pakistan, Turkey, Vietnam, South Africa, Columbia, Bolivia, etc. If you need equipment such as rotary kiln, ball mill, vertical mill, rolling machine , please don't hesitate to contact us.