Description of New Type Dry Process Cement Production Line:

This new type dry process cement production line is a kind of process mainly used for small, medium and large-scale cement plants. Its preheater employs outside kiln precalciner. Capable of utilizing the waste heat from kiln inlet to decompose raw meal, this line is good at saving electricity and heat. Its closed production line makes it possible to reduce its ambient dust pollution to less than 50mg/Nm3. Besides, its capacity to make use waste heat makes it quite cost efficient for users.

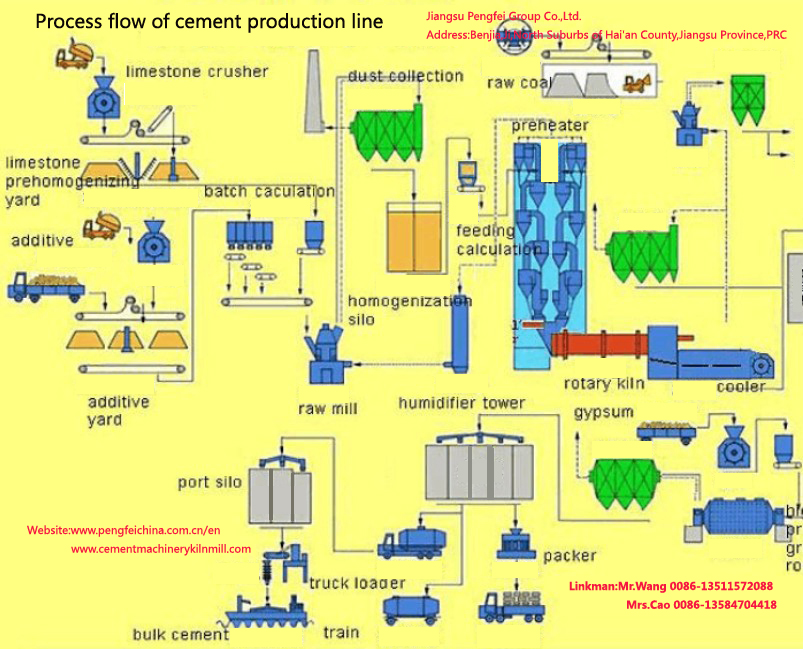

Production Flow of New Type Dry Process Cement Production Line:

1. Crushing and Pre-homogenizing:

Most of the raw materials, like limestone, clay, iron ores, and coal, should be crushed before their pre-homogenization. Limestone is the primary material in this line, and due to its large particle size and high hardness, its good crushing plays an important role in the whole line. Special stacking and reclaiming technology has been used in the pre-homogenizing process so that raw materials can be better primarily homogenized.

2. Raw Meal Preparing:

Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, it is quite important to choose appropriate grinding equipment and technological process so that high-quality products can be obtained.

3. Raw Meal Homogenizing:

The raw meal homogenization is a key factor for stable clinker calcination.

4. Preheating and Decomposing:

The preheater is used to preheat as well as decompose raw meal. So the length of the rotary kiln is effectively shortened. And the raw meal can fully exchange heat with the hot gases from the kiln. Because of its rapid and high-efficiency heat transfer, the production efficiency and heat consumption of this production line are greatly improved.

5. Clinker Calcining:

After its preheating and pre-decomposing, the raw meal will be calcined in the rotary kiln, where the generated carbonate will be further decomposed. Meanwhile, a series of solid phase reactions will take place.

6. Cement Grinding:

As the last process, the cement grinding will consume a great deal of electricity. And in this process, special size granule cement will be obtained.

7. Cement Packaging:

The cement can be transported in bulk or in bags.

日产5000吨新型干法水泥生产线项目报价单

Proposal for 5000tpd new dry process cement production line

1、建设条件

Construction condition

(1)建设规模:一条日产5000吨新型干法水泥生产线。

Construction scope: a unit 5000tpd new dry process cement production line

(2)原料:采用石灰石、砂岩、硫酸渣、废土四组分配料,配料比例为石灰石:砂岩、硫酸渣、废土=80.02:9.72:2.92:7.16

Raw material: uses limestone、sandstone、sulfur acid residue and spent clay four component ingredient; its ingredient proportion ratio: 80.02:9.72:2.92:7.16

(3)全线装机容量:35000KW

Installed capacity of the whole line: 35000KW

2. 主机设备

Main equipments:

| 序号 Sr. No. | 主机名称、规格、型号 Descriptions | 台数 Quantity | 主要技术性能 Main technical Performance | 能力 Capacity | 电机功率 Power of motor | 备注 Remarks |

| (台) (Unit) | (t/h) | (kW) | (%) | |||

| 1 | 单段锤式破碎机 2022F Hammer crusher 2022F | 1 | 出料粒度<75mm Output granulating<75mm | 700 | 800 | |

| 2 | 石灰石预均化堆场 Limestone pre-homogenizing storage shed | 1 | 堆料1000t/h 取料500t/h Stocking capacity: 1000t/h drawing capacity: 500t/h | 储量50000t Storage Capacity: 50000t | ||

| 3 | HRM4800立式磨 HRM4800 vertical mill | 1 | 细度14% Fineness 14% | 400 | 3800 | |

| 4 | HCR5000分解炉预热器 HCR5000 pre-heater with calciner | 1 | 入窑分解率>90% Calcining rate feed to kiln is more than 90% | 230 | ||

| 5 | φ4.8×74m回转窑 φ4.8×74m rotary kiln | 1 | 斜度:4% n=0.6-4.0 Inclination: 4% | 230 | 630 | |

| 6 | 窑气梁篦冷机 Kiln gas beam grate cooler | 1 | 出料温度=环境+65℃ Discharge temperature=ambient +65℃ | 230 | 165 | |

| 7 | HRM2200立式煤磨 HRM2200 vertical coal mill | 1 | 产品细度8% Fineness of product 8% | 45 | 630 | |

| 8 | 高温风机 I.D Fan | 1 | 风量:920000m3/h 风压:8000Pa Air flow: 920000m3/h Pressure: 8000Pa | 2500 | ||

| 9 | 窑尾电收尘器 Electrostatic precipitator at kiln end | 1 | 风量:820000m3/h 排放浓度<50mg/m3 Air flow: 820000m3/h Outlet air dust content:<50mg/m3 | 310m2 | ||

| 10 | 辊压机Roller | 2 | HFCG140/80 | 365 | 500 | |

| 11 | 水泥磨Cement Mill | 2 | φ4.2×13m | 135 | 3550 | |

| 12 | 八嘴回转式包装机 8-spout rotary packing machine | 4 | 八嘴 8 spouts | 120t/h | ||

3、物料储存方式、储存量

Storage form and storage capacity of materials

| 序号 Sr. no. | 物料名称 Name of materials | 储库规格(m) Size of Storage silo (m) | 储存量(t) Storage capacity (t) | 备注 Remarks |

| 1 | 石灰石 Limestone | φ90m预均化堆场 φ90m Pre-homogenizing Storage shed | 47000 | |

| 2 | 原料 Raw material | 42×120m预均化堆场 42×120m Pre-homogenizing Storage shed | 25000 | |

| 3 | 生料Raw meal | φ22.5×52m均化库 φ22.5×52m Homogenizing silo | 17000 | |

| 4 | 熟料Clinker | φ40×50m | 60000 |

=========================================================================================================

As world-known and high-quality cement machinery general contractor, Jiangsu Pengfei Group Co., Ltd can provide you with various machines, such as cement production line, cement grinding plant, active lime production line, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, drying equipment, cooling equipment, compound fertilizer equipment, Conveying Lifting Packing Equipment, Most of our products have passed the certification of ISO9000 and CE, and they have been quite popular among customers from as many as 60 countries and districts such as Germany, Russia, Brazil, Egypt, Japan, South Korea, Bengal, Pakistan, Turkey, Vietnam, South Africa, Columbia, Bolivia, etc. If you need equipment such as rotary kiln, ball mill, vertical mill, rolling machine , please don't hesitate to contact us.